Tackling Challenges and Exploring Opportunities in Cathode Binder Innovation

Corresponding Author: Xiangming He

Nano-Micro Letters,

Vol. 18 (2026), Article Number: 9

Abstract

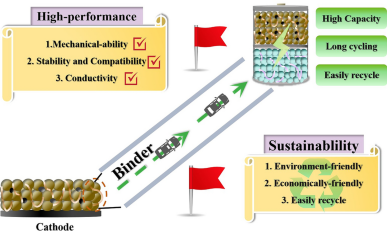

Long-life energy storage batteries are integral to energy storage systems and electric vehicles, with lithium-ion batteries (LIBs) currently being the preferred option for extended usage-life energy storage. To further extend the life span of LIBs, it is essential to intensify investments in battery design, manufacturing processes, and the advancement of ancillary materials. The pursuit of long durability introduces new challenges for battery energy density. The advent of electrode material offers effective support in enhancing the battery's long-duration performance. Often underestimated as part of the cathode composition, the binder plays a pivotal role in the longevity and electrochemical performance of the electrode. Maintaining the mechanical integrity of the electrode through judicious binder design is a fundamental requirement for achieving consistent long-life cycles and high energy density. This paper primarily concentrates on the commonly employed cathode systems in lithium-ion batteries, elucidates the significance of binders for both, discusses the application status, strengths, and weaknesses of novel binders, and ultimately puts forth corresponding optimization strategies. It underscores the critical function of binders in enhancing battery performance and advancing the sustainable development of lithium-ion batteries, aiming to offer fresh insights and perspectives for the design of high-performance LIBs.

Highlights:

1 Binders play a crucial role in the lifespan and performance of electrodes, but they are often overlooked. This paper mainly reviews the significance of the role of binders on cathode materials and the optimization strategies.

2 Focusing on LiFePO₄ and transition metal oxide cathode systems, this review systematically summarizes performance optimization strategies for novel binders tailored to the respective advantages and limitations of different cathodes.

3 The future development trend of cathode binders is analyzed, emphasizing the challenges and opportunities faced by binders in thermal safety and all-solid-state systems.

Keywords

Download Citation

Endnote/Zotero/Mendeley (RIS)BibTeX

- T. Liu, Y. Zhang, Z. Jiang, X. Zeng, J. Ji et al., Exploring competitive features of stationary sodium ion batteries for electrochemical energy storage. Energy Environ. Sci. 12(5), 1512–1533 (2019). https://doi.org/10.1039/C8EE03727B

- M.S. Whittingham, Electrical energy storage and intercalation chemistry. Science 192(4244), 1126–1127 (1976). https://doi.org/10.1126/science.192.4244.1126

- S.H. Lee, C. Johnston, P.S. Grant, Scalable, large-area printing of pore-array electrodes for ultrahigh power electrochemical energy storage. ACS Appl. Mater. Interf. 11(41), 37859–37866 (2019). https://doi.org/10.1021/acsami.9b14478

- S. Ding, L. Wang, H. Dai, X. He, Prognosticating nonlinear degradation in lithium-ion batteries: operando pressure as an early indicator preceding other signals of capacity fade and safety risks. Energy Storage Mater. 75, 103998 (2025). https://doi.org/10.1016/j.ensm.2024.103998

- J. Cai, X. Zhou, L. Li, Z. Yang, X. Huang et al., Kinetically dormant Ni-rich layered cathode during high-voltage operation. Adv. Mater. 37(14), e2419253 (2025). https://doi.org/10.1002/adma.202419253

- L. Tong, J. Ji, Y. Zhao, L. Wang, X. He, The rise of lithium bis(fluorosulfonyl) imide: an efficient alternative to LiPF6 and functional additive in electrolytes. Mater. Today 85, 282–303 (2025). https://doi.org/10.1016/j.mattod.2025.02.018

- Y. Kuk, J. Hwang, D. Nam, J. Kim, Facile synthesis of high-performance LiFePO4-reduced graphene oxide composites using ball milling. Ionics 26(6), 2803–2812 (2020). https://doi.org/10.1007/s11581-019-03395-6

- J. Liu, B. Ludwig, Y. Liu, H. Pan, Y. Wang, Strengthening the electrodes for Li-ion batteries with a porous adhesive interlayer through dry-spraying manufacturing. ACS Appl. Mater. Interf. 11(28), 25081–25089 (2019). https://doi.org/10.1021/acsami.9b03020

- S. Dong, L. Wang, X. Huang, J. Liang, X. He, Functionalized binders boost high-capacity anode materials. Adv. Funct. Mater. 34(41), 2404192 (2024). https://doi.org/10.1002/adfm.202404192

- H. Cui, L. Wang, Y. Song, T. Lai, Z. Liu et al., Understanding electrolyte infiltration mechanisms in high-density battery electrodes: a multimodal approach. Energy Storage Mater. 75, 104094 (2025). https://doi.org/10.1016/j.ensm.2025.104094

- C. Yang, D.J. Lee, H. Kim, K. Kim, J. Joo et al., Synthesis of nano-sized urchin-shaped LiFePO4 for lithium ion batteries. RSC Adv. 9(24), 13714–13721 (2019). https://doi.org/10.1039/c9ra00897g

- J. Ou, L. Yang, F. Jin, S. Wu, J. Wang, High performance of LiFePO4 with nitrogen-doped carbon layers for lithium ion batteries. Adv. Powder Technol. 31(3), 1220–1228 (2020). https://doi.org/10.1016/j.apt.2019.12.044

- P. Wang, G. Zhang, Z. Li, W. Sheng, Y. Zhang et al., Improved electrochemical performance of LiFePO4@N-doped carbon nanocomposites using polybenzoxazine as nitrogen and carbon sources. ACS Appl. Mater. Interf. 8(40), 26908–26915 (2016). https://doi.org/10.1021/acsami.6b10594

- S.S. Zhang, K. Xu, T.R. Jow, Evaluation on a water-based binder for the graphite anode of Li-ion batteries. J. Power. Sour. 138(1–2), 226–231 (2004). https://doi.org/10.1016/j.jpowsour.2004.05.056

- J.-H. Lee, S. Lee, U. Paik, Y.-M. Choi, Aqueous processing of natural graphite particulates for lithium-ion battery anodes and their electrochemical performance. J. Power. Sour. 147(1–2), 249–255 (2005). https://doi.org/10.1016/j.jpowsour.2005.01.022

- Z. Zhang, T. Zeng, C. Qu, H. Lu, M. Jia et al., Cycle performance improvement of LiFePO4 cathode with polyacrylic acid as binder. Electrochim. Acta 80, 440–444 (2012). https://doi.org/10.1016/j.electacta.2012.07.054

- J.S. Kim, W. Choi, K.Y. Cho, D. Byun, J. Lim et al., Effect of polyimide binder on electrochemical characteristics of surface-modified silicon anode for lithium ion batteries. J. Power. Sour. 244, 521–526 (2013). https://doi.org/10.1016/j.jpowsour.2013.02.049

- Z. Zhang, T. Zeng, Y. Lai, M. Jia, J. Li, A comparative study of different binders and their effects on electrochemical properties of LiMn2O4 cathode in lithium ion batteries. J. Power. Sour. 247, 1–8 (2014). https://doi.org/10.1016/j.jpowsour.2013.08.051

- S.S. Zhang, T.R. Jow, Study of poly(acrylonitrile-methyl methacrylate) as binder for graphite anode and LiMn2O4 cathode of Li-ion batteries. J. Power. Sour. 109(2), 422–426 (2002). https://doi.org/10.1016/S0378-7753(02)00107-6

- I. Doberdò, N. Löffler, N. Laszczynski, D. Cericola, N. Penazzi et al., Enabling aqueous binders for lithium battery cathodes–Carbon coating of aluminum current collector. J. Power. Sour. 248, 1000–1006 (2014). https://doi.org/10.1016/j.jpowsour.2013.10.039

- J. He, H. Zhong, J. Wang, L. Zhang, Investigation on xanthan gum as novel water soluble binder for LiFePO4 cathode in lithium-ion batteries. J. Alloys Compd. 714, 409–418 (2017). https://doi.org/10.1016/j.jallcom.2017.04.238

- W. Zheng, S. Zhou, X. Yang, P. Wang, N. Luo et al., Mechanistic investigation of a novel aqueous binder CMC-NH4 enriched with electronegative elements on the performance of LiFePO4 cathode. J. Appl. Electrochem. (2025). https://doi.org/10.1007/s10800-025-02286-1

- J. Neumann, M. Petranikova, M. Meeus, J.D. Gamarra, R. Younesi et al., Recycling of lithium-ion batteries: current state of the art, circular economy, and next generation recycling. Adv. Energy Mater. 12(17), 2102917 (2022). https://doi.org/10.1002/aenm.202102917

- L. Wang, Y. Shen, Y. Liu, P. Zeng, J. Meng et al., Electrochemical restoration of battery materials guided by synchrotron radiation technology for sustainable lithium-ion batteries. Small Meth. 7(9), 2201658 (2023). https://doi.org/10.1002/smtd.202201658

- J. Shim, R. Kostecki, T. Richardson, X. Song, K.A. Striebel, Electrochemical analysis for cycle performance and capacity fading of a lithium-ion battery cycled at elevated temperature. J. Power. Sour. 112(1), 222–230 (2002). https://doi.org/10.1016/S0378-7753(02)00363-4

- Y. Zhang, C.-Y. Wang, X. Tang, Cycling degradation of an automotive LiFePO4 lithium-ion battery. J. Power. Sour. 196(3), 1513–1520 (2011). https://doi.org/10.1016/j.jpowsour.2010.08.070

- H.-M. Kim, B.-I. Yoo, J.-W. Yi, M.-J. Choi, J.-K. Yoo, Solvent-free fabrication of thick electrodes in thermoplastic binders for high energy density lithium-ion batteries. Nanomaterials 12(19), 3320 (2022). https://doi.org/10.3390/nano12193320

- Y. Kuang, C. Chen, D. Kirsch, L. Hu, Thick electrode batteries: principles, opportunities, and challenges. Adv. Energy Mater. 9(33), 1901457 (2019). https://doi.org/10.1002/aenm.201901457

- X. Li, M. Wang, Q. Zhou, M. Ge, M. Zhang et al., The prilling and cocoating collaborative strategy to construct high performance of regeneration LiFePO4 materials. ACS Mater. Lett. 6(2), 640–647 (2024). https://doi.org/10.1021/acsmaterialslett.3c01161

- L. Yang, Y. Tian, J. Chen, J. Gao, Z. Long et al., A high-rate capability LiFePO4/C cathode achieved by the modulation of the band structures. J. Mater. Chem. A 9(43), 24686–24694 (2021). https://doi.org/10.1039/d1ta07757k

- J. Lin, Y.-H. Sun, X. Lin, Metal-organic framework-derived LiFePO4 cathode encapsulated in O, F-codoped carbon matrix towards superior lithium storage. Nano Energy 91, 106655 (2022). https://doi.org/10.1016/j.nanoen.2021.106655

- A. Börger, J. Mertens, H. Wenzl, Thermal runaway and thermal runaway propagation in batteries: What do we talk about? J. Energy Storage 24, 100649 (2019). https://doi.org/10.1016/j.est.2019.01.012

- X. Feng, M. Ouyang, X. Liu, L. Lu, Y. Xia et al., Thermal runaway mechanism of lithium ion battery for electric vehicles: a review. Energy Storage Mater. 10, 246–267 (2018). https://doi.org/10.1016/j.ensm.2017.05.013

- X. Feng, S. Zheng, D. Ren, X. He, L. Wang et al., Investigating the thermal runaway mechanisms of lithium-ion batteries based on thermal analysis database. Appl. Energy 246, 53–64 (2019). https://doi.org/10.1016/j.apenergy.2019.04.009

- H. Zhou, M. Parmananda, K.R. Crompton, M.P. Hladky, M.A. Dann et al., Effect of electrode crosstalk on heat release in lithium-ion batteries under thermal abuse scenarios. Energy Storage Mater. 44, 326–341 (2022). https://doi.org/10.1016/j.ensm.2021.10.030

- J.E. Marshall, A. Zhenova, S. Roberts, T. Petchey, P. Zhu et al., On the solubility and stability of polyvinylidene fluoride. Polymers 13(9), 1354 (2021). https://doi.org/10.3390/polym13091354

- M.N. Richard, J.R. Dahn, Accelerating rate calorimetry study on the thermal stability of lithium intercalated graphite in electrolyte. II. modeling the results and predicting differential scanning calorimeter curves. J. Electrochem. Soc. 146(6), 2078–2084 (1999). https://doi.org/10.1149/1.1391894

- H. Maleki, G. Deng, I. Kerzhner-Haller, A. Anani, J.N. Howard, Thermal stability studies of binder materials in anodes for lithium-ion batteries. J. Electrochem. Soc. 147(12), 4470 (2000). https://doi.org/10.1149/1.1394088

- A. Kriston, I. Adanouj, V. Ruiz, A. Pfrang, Quantification and simulation of thermal decomposition reactions of Li-ion battery materials by simultaneous thermal analysis coupled with gas analysis. J. Power. Sources 435, 226774 (2019). https://doi.org/10.1016/j.jpowsour.2019.226774

- J. Janek, W.G. Zeier, A solid future for battery development. Nat. Energy 1(9), 16141 (2016). https://doi.org/10.1038/nenergy.2016.141

- Y.-K. Sun, Promising all-solid-state batteries for future electric vehicles. ACS Energy Lett. 5(10), 3221–3223 (2020). https://doi.org/10.1021/acsenergylett.0c01977

- H. Huo, J. Janek, Solid-state batteries: from ‘all-solid’ to ‘almost-solid.’ Natl. Sci. Rev. 10(6), nwas098 (2023). https://doi.org/10.1093/nsr/nwad098

- Y. Zhao, Z. Liang, Y. Kang, Y. Zhou, Y. Li et al., Rational design of functional binder systems for high-energy lithium-based rechargeable batteries. Energy Storage Mater. 35, 353–377 (2021). https://doi.org/10.1016/j.ensm.2020.11.021

- C. Shen, H. Yu, Z. Xue, G. Hu, Y. Cao et al., Bifunctional low molecular weight polyacrylic acid as aqueous binder and coating agent enables high performance LiMn2O4 cathode for lithium-ion batteries. Chem. Eng. J. 489, 151287 (2024). https://doi.org/10.1016/j.cej.2024.151287

- W. Qi, R. Han, H. Quan, R. Guo, D. Gao et al., Self-reducing molecular ink for printed electronics and lithium-ion battery cathodes as conductive binder. J. Mater. Chem. C 12(14), 5114–5121 (2024). https://doi.org/10.1039/D3TC03636G

- N. Kumano, Y. Yamaguchi, Y. Akimoto, A. Ohshima, H. Nakamura et al., Migration of binder and conductive agent during drying process of Li-ion battery cathodes. J. Power. Sources 591, 233883 (2024). https://doi.org/10.1016/j.jpowsour.2023.233883

- S.-B. Hong, Y.-R. Jang, H. Kim, Y.-C. Jung, G. Shin et al., Wet-processable binder in composite cathode for high energy density all-solid-state lithium batteries. Adv. Energy Mater. 14(35), 2400802 (2024). https://doi.org/10.1002/aenm.202400802

- L. Deng, J.-K. Liu, Z. Wang, J.-X. Lin, Y.-X. Liu et al., A formula to customize cathode binder for lithium ion battery. Adv. Energy Mater. 14(40), 2401514 (2024). https://doi.org/10.1002/aenm.202401514

- P. Das, C.Z. Salamat, B. Zayat, R. Elizalde-Segovia, Y. Wang et al., Evaluating the impact of conjugation break spacer incorporation in poly(3, 4-propylenedioxythiophene)-based cathode binders for lithium-ion batteries. Chem. Mater. 36(3), 1413–1427 (2024). https://doi.org/10.1021/acs.chemmater.3c02555

- Q. Gan, N. Qin, H. Guo, F. Zhang, H. Yuan et al., Consolidating the vulnerable interphase of Ni-rich layered cathode by multifunctional water-based binder. ACS Energy Lett. 9(4), 1562–1571 (2024). https://doi.org/10.1021/acsenergylett.4c00307

- C. Li, S. Nie, H. Li, Towards efficient polymeric binders for transition metal oxides-based Li-ion battery cathodes. Chem. 30(16), e202303733 (2024). https://doi.org/10.1002/chem.202303733

- M.S. Ziegler, J. Song, J.E. Trancik, Determinants of lithium-ion battery technology cost decline. Energy Environ. Sci. 14(12), 6074–6098 (2021). https://doi.org/10.1039/d1ee01313k

- S. Huo, L. Sheng, W. Xue, L. Wang, H. Xu et al., Challenges of stable ion pathways in cathode electrode for all-solid-state lithium batteries: a review. Adv. Energy Mater. 13(15), 2204343 (2023). https://doi.org/10.1002/aenm.202204343

- A. Mathew, W. van Ekeren, R. Andersson, M.J. Lacey, S.K. Heiskanen et al., Limitations of polyacrylic acid binders when employed in thick LNMO Li-ion battery electrodes. J. Electrochem. Soc. 171(2), 020531 (2024). https://doi.org/10.1149/1945-7111/ad242b

- Q. He, J. Ning, H. Chen, Z. Jiang, J. Wang et al., Achievements, challenges, and perspectives in the design of polymer binders for advanced lithium-ion batteries. Chem. Soc. Rev. 53(13), 7091–7157 (2024). https://doi.org/10.1039/d4cs00366g

- J.-O. Kim, E. Kim, E.Y. Lim, T. Kwon, I.-J. Kim et al., Stress-dissipative elastic waterborne polyurethane binders for silicon anodes with high structural integrity in lithium-ion batteries. ACS Appl. Energy Mater. 7(4), 1629–1639 (2024). https://doi.org/10.1021/acsaem.3c03099

- Y. He, F. Zhou, Y. Zhang, T. Lv, P.K. Chu et al., A triple crosslinked binder with hierarchical stress dissipation and high ionic conductivity for advanced silicon anodes in lithium-ion batteries. Small 20(45), 2404556 (2024). https://doi.org/10.1002/smll.202404556

- Q. Shi, S.-C. Wong, W. Ye, J. Hou, J. Zhao et al., Mechanism of adhesion between polymer fibers at nanoscale contacts. Langmuir 28(10), 4663–4671 (2012). https://doi.org/10.1021/la204633c

- A. Saal, T. Hagemann, U.S. Schubert, Polymers for battery applications: active materials, membranes, and binders. Adv. Energy Mater. 11(43), 2001984 (2021). https://doi.org/10.1002/aenm.202001984

- D. Shin, H. Park, U. Paik, Cross-linked poly(acrylic acid)-carboxymethyl cellulose and styrene-butadiene rubber as an efficient binder system and its physicochemical effects on a high energy density graphite anode for Li-ion batteries. Electrochem. Commun. 77, 103–106 (2017). https://doi.org/10.1016/j.elecom.2017.02.018

- S. Huang, X. Huang, Y. Huang, X. He, H. Zhuo et al., Rational design of effective binders for LiFePO4 cathodes. Polymers 13(18), 3146 (2021). https://doi.org/10.3390/polym13183146

- S. Hu, Y. Li, J. Yin, H. Wang, X. Yuan et al., Effect of different binders on electrochemical properties of LiFePO4/C cathode material in lithium ion batteries. Chem. Eng. J. 237, 497–502 (2014). https://doi.org/10.1016/j.cej.2013.08.119

- J.L. Olmedo-Martínez, L. Meabe, A. Basterretxea, D. Mecerreyes, A.J. Müller, Effect of chemical structure and salt concentration on the crystallization and ionic conductivity of aliphatic polyethers. Polymers 11(3), 452 (2019). https://doi.org/10.3390/polym11030452

- Y. Komoda, K. Ishibashi, K. Kuratani, K. Suzuki, N. Ohmura et al., Effects of drying rate and slurry microstructure on the formation process of LiB cathode and electrochemical properties. J. Power. Sour. 568, 232983 (2023). https://doi.org/10.1016/j.jpowsour.2023.232983

- A.D. Pasquier, F. Disma, T. Bowmer, A.S. Gozdz, G. Amatucci et al., Differential scanning calorimetry study of the reactivity of carbon anodes in plastic Li-ion batteries. J. Electrochem. Soc. 145(2), 472–477 (1998). https://doi.org/10.1149/1.1838287

- J. Liang, D. Chen, K. Adair, Q. Sun, N.G. Holmes et al., Insight into prolonged cycling life of 4 V all-solid-state polymer batteries by a high-voltage stable binder. Adv. Energy Mater. 11(1), 2002455 (2021). https://doi.org/10.1002/aenm.202002455

- R. Wang, L. Feng, W. Yang, Y. Zhang, Y. Zhang et al., Effect of different binders on the electrochemical performance of metal oxide anode for lithium-ion batteries. Nanoscale Res. Lett. 12(1), 575 (2017). https://doi.org/10.1186/s11671-017-2348-6

- A. Fedorková, R. Oriňáková, A. Oriňák, I. Talian, A. Heile et al., PPy doped PEG conducting polymer films synthesized on LiFePO4 ps. J. Power. Sour. 195(12), 3907–3912 (2010). https://doi.org/10.1016/j.jpowsour.2010.01.003

- S. Roberts, L. Chen, B. Kishore, C.E.J. Dancer, M.J.H. Simmons et al., Mechanism of gelation in high nickel content cathode slurries for sodium-ion batteries. J. Colloid Interf. Sci. 627, 427–437 (2022). https://doi.org/10.1016/j.jcis.2022.07.033

- C.-H. Tsao, C.-H. Hsu, P.-L. Kuo, Ionic Conducting and Surface Active Binder of Poly (ethylene oxide)-block-poly(acrylonitrile) for High Power Lithium-ion Battery. Electrochim. Acta 196, 41–47 (2016). https://doi.org/10.1016/j.electacta.2016.02.154

- I. Aldalur, H. Zhang, M. Piszcz, U. Oteo, L.M. Rodriguez-Martinez et al., Jeffamine® based polymers as highly conductive polymer electrolytes and cathode binder materials for battery application. J. Power. Sour. 347, 37–46 (2017). https://doi.org/10.1016/j.jpowsour.2017.02.047

- A.C. Luntz, B.D. McCloskey, Nonaqueous Li-air batteries: a status report. Chem. Rev. 114(23), 11721–11750 (2014). https://doi.org/10.1021/cr500054y

- B. Chang, D.H. Yun, I. Hwang, J.K. Seo, J. Kang et al., Carrageenan as a sacrificial binder for 5 V LiNi0.5 Mn1.5 O4 cathodes in lithium-ion batteries. Adv. Mater. 35(45), e2303787 (2023). https://doi.org/10.1002/adma.202303787

- A. Guerfi, M. Kaneko, M. Petitclerc, M. Mori, K. Zaghib, LiFePO4 water-soluble binder electrode for Li-ion batteries. J. Power. Sour. 163(2), 1047–1052 (2007). https://doi.org/10.1016/j.jpowsour.2006.09.067

- H. Tang, Q. Weng, Z. Tang, Chitosan oligosaccharides: a novel and efficient water soluble binder for lithium zinc titanate anode in lithium-ion batteries. Electrochim. Acta 151, 27–34 (2015). https://doi.org/10.1016/j.electacta.2014.11.002

- X. Liu, M. Zhang, X. Peng, M. Li et al., Se–Se bonds involved polyurethane-based binders for enhanced redox kinetics in lithium-ion batteries. ACS Appl. Polym. Mater. 7(6), 4019–4028 (2025). https://doi.org/10.1021/acsapm.5c00401

- C. Liang, Z. Li, Y. Chen, Y. Zhang, Y. Liu et al., Design and preparation of soluble polyimide binder with random copolymerized rigid-flexible segments for lithium ion batteries. J. Appl. Polym. Sci. 142(14), e56709 (2025). https://doi.org/10.1002/app.56709

- Y. Hu, C. Wang, G. Zhu, J. Xu, L. Wang et al., POLY(amidoamine) dendrimer-induced 3D crosslinked network binder for LiFePO4 cathode: endowing battery with superior cycling stability. J. Electrochem. Soc. 170(3), 030547 (2023). https://doi.org/10.1149/1945-7111/acc6f4

- F. Zhang, H. Xia, T. Wei, B. Liu, H. Li et al., Rotatable methylene ether bridge units enabling high chain flexibility and rapid ionic transport in a new universal aqueous conductive binder. Adv. Funct. Mater. 33(34), 2303339 (2023). https://doi.org/10.1002/adfm.202303339

- Y. Xu, Y. Wang, N. Dong, C. Pu, B. Liu et al., Novel polyimide binder for achieving high-rate capability and long-term cycling stability of LiNi0.8Co0.1Mn0.1O2 cathode via constructing polar and micro-branched crosslinking network structure. J. Energy Chem. 76, 19–31 (2023). https://doi.org/10.1016/j.jechem.2022.09.008

- C. Ye, L. Wang, Q. Tan, Y. Ma, Q. Tong et al., Conducting polyacrylamide–polyaniline polymers as water-soluble binder in LiFePO4 cathode for lithium-ion batteries. Energy Technol. 11(9), 2300464 (2023). https://doi.org/10.1002/ente.202300464

- J. He, J. Wang, H. Zhong, J. Ding, L. Zhang, Cyanoethylated carboxymethyl chitosan as water soluble binder with enhanced adhesion capability and electrochemical performances for LiFePO4 cathode. Electrochim. Acta 182, 900–907 (2015). https://doi.org/10.1016/j.electacta.2015.10.006

- J. Huang, J. Wang, H. Zhong, L. Zhang, N-cyanoethyl polyethylenimine as a water-soluble binder for LiFePO4 cathode in lithium-ion batteries. J. Mater. Sci. 53(13), 9690–9700 (2018). https://doi.org/10.1007/s10853-018-2247-y

- J.-C. Daigle, F. Barray, C. Gagnon, D. Clément, P. Hovington et al., Amphiphilic latex as a water-based binder for LiFePO4 cathode. J. Power. Sour. 415, 172–178 (2019). https://doi.org/10.1016/j.jpowsour.2019.01.054

- H. Peng, L. Liu, Q. Zhang, S. Liu, M. Lin et al., A fluorine-free polysulfone-polyamide-polyimide copolymer binder for LiNi0.8Co0.1Mn0.1O2 cathode in lithium-ion battery. Chin. J. Polym. Sci. (2025). https://doi.org/10.1007/s10118-025-3281-2

- Y. Wang, N. Dong, B. Liu, G. Tian, S. Qi et al., Self-adaptive gel poly(imide-siloxane) binder ensuring stable cathode-electrolyte interface for achieving high-performance NCM811 cathode in lithium-ion batteries. Energy Storage Mater. 56, 621–630 (2023). https://doi.org/10.1016/j.ensm.2023.02.002

- J. He, H. Zhong, L. Zhang, Water-soluble binder PAALi with terpene resin emulsion as tackifier for LiFePO4 cathode. J. Appl. Polym. Sci. 135(14), 46132 (2018). https://doi.org/10.1002/app.46132

- A. Oishi, R. Tatara, E. Togo, H. Inoue, S. Yasuno et al., Sulfated alginate as an effective polymer binder for high-voltage LiNi0.5Mn1.5O4 electrodes in lithium-ion batteries. ACS Appl. Mater. Interfaces 14(46), 51808–51818 (2022). https://doi.org/10.1021/acsami.2c11695

- D. Shao, J. Huang, A. Wu, Y. Fang, X. Li et al., Synthesis of N-ethyl carboxylic acid functionalized polyethylenimine as self-crosslinking aqueous binder for LiFePO4 cathode of lithium-ion batteries. Energy Technol. 13(5), 2402066 (2025). https://doi.org/10.1002/ente.202402066

- A. Weber, N. Keim, P. Koch, M. Müller, W. Bauer et al., The impact of binder polarity on the properties of aqueously processed positive and negative electrodes for lithium-ion batteries. Sci. Rep. 15(1), 10024 (2025). https://doi.org/10.1038/s41598-025-93813-9

- P.P. Prosini, M. Carewska, C. Cento, A. Masci, Poly vinyl acetate used as a binder for the fabrication of a LiFePO4-based composite cathode for lithium-ion batteries. Electrochim. Acta 150, 129–135 (2014). https://doi.org/10.1016/j.electacta.2014.10.123

- M. Sun, H. Zhong, S. Jiao, H. Shao, L. Zhang, Investigation on carboxymethyl chitosan as new water soluble binder for LiFePO4 cathode in Li-ion batteries. Electrochim. Acta 127, 239–244 (2014). https://doi.org/10.1016/j.electacta.2014.02.027

- W. Porcher, B. Lestriez, S. Jouanneau, D. Guyomard, Design of aqueous processed thick LiFePO4 composite electrodes for high-energy lithium battery. J. Electrochem. Soc. 156(3), A133 (2009). https://doi.org/10.1149/1.3046129

- G.T. Kim, S.S. Jeong, M. Joost, E. Rocca, M. Winter et al., Use of natural binders and ionic liquid electrolytes for greener and safer lithium-ion batteries. J. Power. Sour. 196(4), 2187–2194 (2011). https://doi.org/10.1016/j.jpowsour.2010.09.080

- Z.P. Cai, Y. Liang, W.S. Li, L.D. Xing, Y.H. Liao, Preparation and performances of LiFePO4 cathode in aqueous solvent with polyacrylic acid as a binder. J. Power. Sour. 189(1), 547–551 (2009). https://doi.org/10.1016/j.jpowsour.2008.10.040

- Z. Zhang, T. Zeng, H. Lu, M. Jia, J. Li et al., Enhanced high-temperature performances of LiFePO4 cathode with polyacrylic acid as binder. ECS Electrochem. Lett. 1(5), A74–A76 (2012). https://doi.org/10.1149/2.001206eel

- J. Sun, X. Ren, Z. Li, W. Tian, Y. Zheng et al., Effect of poly (acrylic acid)/Poly (vinyl alcohol) blending binder on electrochemical performance for lithium iron phosphate cathodes. J. Alloys Compd. 783, 379–386 (2019). https://doi.org/10.1016/j.jallcom.2018.12.197

- C.-C. Li, Y.-S. Lin, Interactions between organic additives and active powders in water-based lithium iron phosphate electrode slurries. J. Power. Sour. 220, 413–421 (2012). https://doi.org/10.1016/j.jpowsour.2012.07.125

- Y. Wang, M. Ji, T. Zhu, L. Wang, Y. Zhou et al., Multifunctional amino-functionalized Zr-based metal-organic frameworks: a breakthrough in enhancing the stability and performance of Ni-rich cathode Li metal batteries in water-prone environments. Energy Storage Mater. 77, 104217 (2025). https://doi.org/10.1016/j.ensm.2025.104217

- A.C. Rolandi, C. Pozo-Gonzalo, I. de Meatza, N. Casado, D. Mecerreyes et al., Fluorine-free poly(ionic liquid)s binders for the aqueous processing of high-voltage NMC811 cathodes. Adv. Energy Sustain. Res. 4(12), 2300149 (2023). https://doi.org/10.1002/aesr.202300149

- L. Rao, X. Jiao, C.-Y. Yu, A. Schmidt, C. O’Meara et al., Multifunctional composite binder for thick high-voltage cathodes in lithium-ion batteries. ACS Appl. Mater. Interf. 14(1), 861–872 (2022). https://doi.org/10.1021/acsami.1c19554

- J. Shin, J.-H. Lee, J.K. Seo, W.T.A. Ran, S.M. Hwang et al., Carbon nanotubes-coated Ni-rich cathodes for the green manufacturing process of lithium-ion batteries. Int. J. Energy Res. 46(11), 16061–16074 (2022). https://doi.org/10.1002/er.8266

- M. Ryu, Y.K. Hong, S.Y. Lee, J.H. Park, Ultrahigh loading dry-process for solvent-free lithium-ion battery electrode fabrication. Nat. Commun. 14(1), 1316 (2023). https://doi.org/10.1038/s41467-023-37009-7

- H. Kim, J.H. Lim, T. Lee, J. An, H. Kim et al., Ozone-treated carbon nanotube as a conductive agent for dry-processed lithium-ion battery cathode. ACS Energy Lett. 8(8), 3460–3466 (2023). https://doi.org/10.1021/acsenergylett.3c00936

- E. Wiegmann, S. Fischer, M. Leeb, A. Kwade, Sustainable lithium Ferro-phosphate cathode manufacturing: a semi-dry approach with water-based processing and polytetrafluorethylene binders. Batteries 9(12), 567 (2023). https://doi.org/10.3390/batteries9120567

- Z. Zhang, D. Han, M. Xiao, S. Wang, Y. Feng et al., New potential substitute of PVDF binder: poly(propylene carbonate) for solvent-free manufacturing high-loading cathodes of LiFePO4|Li batteries. Ionics 29(10), 3895–3906 (2023). https://doi.org/10.1007/s11581-023-05108-6

- B. Emley, C. Wu, L. Zhao, Q. Ai, Y. Liang et al., Impact of fabrication methods on binder distribution and charge transport in composite cathodes of all-solid-state batteries. Mater. Futur. 2(4), 045102 (2023). https://doi.org/10.1088/2752-5724/acefe6

- S.-B. Hong, Y.-J. Lee, U.-H. Kim, C. Bak, Y.M. Lee et al., All-solid-state lithium batteries: Li+-conducting ionomer binder for dry-processed composite cathodes. ACS Energy Lett. 7(3), 1092–1100 (2022). https://doi.org/10.1021/acsenergylett.1c02756

- T.J. Embleton, J.H. Choi, S.-J. Won, J. Ali, K.S. Saqib et al., High-energy density ultra-thick drying-free Ni-rich cathode electrodes for application in Lithium-ion batteries. Energy Storage Mater. 71, 103542 (2024). https://doi.org/10.1016/j.ensm.2024.103542

- A.C. Kıgılcım, M.E. Cetintasoglu, İ. University, M. Tokur et al., Versatile spiro-fluorene-based polymer binder for Li-ion batteries. ACS Appl. Polym. Mater. 7(4), 2708–2715 (2025). https://doi.org/10.1021/acsapm.5c00081

- R. Jeong, J. Lee, Y.-T. Kim, J. Choi, Lithiated cellulose nanofibers as a water-soluble binder for high-rate nanosized LiFePO4/C cathodes: Comparative degradation mechanisms across binder systems. Chem. Eng. J. 510, 161668 (2025). https://doi.org/10.1016/j.cej.2025.161668

- Y. Yu, C. Yang, Y. Jiang, J. Zhu, J. Zhang et al., Consecutive covalent bonds reconstruct robust dual-interfaces by carbonized binder to enable conductive-additive-free durable silicon anode. Nano Energy 130, 110108 (2024). https://doi.org/10.1016/j.nanoen.2024.110108

- X. Lu, G.J. Lian, J. Parker, R. Ge, M.K. Sadan et al., Effect of carbon blacks on electrical conduction and conductive binder domain of next-generation lithium-ion batteries. J. Power. Sour. 592, 233916 (2024). https://doi.org/10.1016/j.jpowsour.2023.233916

- W. Geng, X. Hu, Q. Zhou, Y. Zhang, B. He et al., Rational design of trifunctional conductive binder for high-performance Si anodes in lithium-ion batteries. J. Power. Sour. 601, 234285 (2024). https://doi.org/10.1016/j.jpowsour.2024.234285

- R. Del Olmo, G. Guzmán-González, O. Sanz, M. Forsyth, N. Casado, Versatile mixed ionic-electronic conducting binders for high-power, high-energy batteries. Electrochim. Acta 474, 143547 (2024). https://doi.org/10.1016/j.electacta.2023.143547

- Q. Zhang, Z. Sha, X. Cui, S. Qiu, C. He et al., Incorporation of redox-active polyimide binder into LiFePO4 cathode for high-rate electrochemical energy storage. Nanotechnol. Rev. 9(1), 1350–1358 (2020). https://doi.org/10.1515/ntrev-2020-0092

- T. Tamura, Y. Aoki, T. Ohsawa, K. Dokko, Polyaniline as a functional binder for LiFePO4 cathodes in lithium batteries. Chem. Lett. 40(8), 828–830 (2011). https://doi.org/10.1246/cl.2011.828

- S. Huang, H. Chen, M. Chen, Y. Huang, X. He et al., Design of conductive binders for LiFePO4 cathodes with long-term cycle life. ACS Sustain. Chem. Eng. 9(39), 13277–13286 (2021). https://doi.org/10.1021/acssuschemeng.1c04552

- T. Liu, R. Parekh, P. Mocny, B.P. Bloom, Y. Zhao et al., Tailored PVDF graft copolymers via ATRP as high-performance NCM811 cathode binders. ACS Mater. Lett. 5(10), 2594–2603 (2023). https://doi.org/10.1021/acsmaterialslett.3c00485

- L. Qiu, Z. Shao, D. Wang, W. Wang, F. Wang et al., Enhanced electrochemical properties of LiFePO4 (LFP) cathode using the carboxymethyl cellulose lithium (CMC-Li) as novel binder in lithium-ion battery. Carbohydr. Polym. 111, 588–591 (2014). https://doi.org/10.1016/j.carbpol.2014.05.027

- L. Qiu, Z. Shao, W. Wang, F. Wang, J. Wang et al., Enhanced Cyclability of C/Lithium Iron Phosphate Cathodes with a Novel water-soluble lithium-ion binder. Electrochim. Acta 145, 11–18 (2014). https://doi.org/10.1016/j.electacta.2014.08.042

- X. Su, H. Fang, H. Yang, F. Zou, G. Li et al., Cellulose sulfate lithium as a conductive binder for LiFePO4 cathode with long cycle life. Carbohydr. Polym. 313, 120848 (2023). https://doi.org/10.1016/j.carbpol.2023.120848

- S. Huang, J. Ren, R. Liu, Y. Bai, X. Li et al., Enhanced electrochemical properties of LiFePO4 cathode using waterborne lithiated ionomer binder in Li-ion batteries with low amount. ACS Sustain. Chem. Eng. 6(10), 12650–12657 (2018). https://doi.org/10.1021/acssuschemeng.8b01532

- M. Ghahramani, S. Hamidi, M. Mohammad, M. Javanbakht, P. Gorji, The effect of sulfonated copolymer as a binder on the electrochemical performance of LiFePO4 cathode for lithium-ion batteries. J. Electroanal. Chem. 936, 117342 (2023). https://doi.org/10.1016/j.jelechem.2023.117342

- V.A. Nguyen, C. Kuss, Review: conducting polymer-based binders for lithium-ion batteries and beyond. J. Electrochem. Soc. 167(6), 065501 (2020). https://doi.org/10.1149/1945-7111/ab856b

- T. Liu, C.-J. Tong, B. Wang, L.-M. Liu, S. Zhang et al., Trifunctional electrode additive for high active material content and volumetric lithium-ion electrode densities. Adv. Energy Mater. 9(10), 1803390 (2019). https://doi.org/10.1002/aenm.201803390

- S.N. Eliseeva, O.V. Levin, E.G. Tolstopjatova, E.V. Alekseeva, R.V. Apraksin et al., New functional conducting poly-3, 4-ethylenedioxythiopene: polystyrene sulfonate/carboxymethylcellulose binder for improvement of capacity of LiFePO4-based cathode materials. Mater. Lett. 161, 117–119 (2015). https://doi.org/10.1016/j.matlet.2015.08.078

- H. Zhong, A. He, J. Lu, M. Sun, J. He et al., Carboxymethyl chitosan/conducting polymer as water-soluble composite binder for LiFePO4 cathode in lithium ion batteries. J. Power. Sour. 336, 107–114 (2016). https://doi.org/10.1016/j.jpowsour.2016.10.041

- A.V. Kubarkov, O.A. Drozhzhin, E.A. Karpushkin, K.J. Stevenson, E.V. Antipov et al., Poly(3, 4-ethylenedioxythiophene): poly(styrenesulfonic acid)–polymer composites as functional cathode binders for high power LiFePO4 batteries. Colloid Polym. Sci. 297(3), 475–484 (2019). https://doi.org/10.1007/s00396-018-04468-0

- W. Dou, G. Wan, T. Liu, L. Han, W. Zhang et al., Conductive composite binder for recyclable LiFePO4 cathode. Chin. Chem. Lett. 35(11), 109389 (2024). https://doi.org/10.1016/j.cclet.2023.109389

- S. Dong, K. Zhu, X. Dong, G. Dong, Y. Gao et al., A novel graphene based bi-function humidity tolerant binder for lithium-ion battery. Small Meth. 7(7), 2201393 (2023). https://doi.org/10.1002/smtd.202201393

- G.T. Pace, M.L. Le, R.J. Clément, R.A. Segalman, A coacervate-based mixed-conducting binder for high-power, high-energy batteries. ACS Energy Lett. 8(6), 2781–2788 (2023). https://doi.org/10.1021/acsenergylett.3c00829

- Y.-K. Hong, J.-H. Kim, N.-Y. Kim, K.-S. Oh, H.-I. Kim et al., Cellulose elementary fibrils as deagglomerated binder for high-mass-loading lithium battery electrodes. Nano-Micro Lett. 17(1), 112 (2025). https://doi.org/10.1007/s40820-024-01642-8

- Y. Shi, X. Zhou, J. Zhang, A.M. Bruck, A.C. Bond et al., Nanostructured conductive polymer gels as a general framework material to improve electrochemical performance of cathode materials in Li-ion batteries. Nano Lett. 17(3), 1906–1914 (2017). https://doi.org/10.1021/acs.nanolett.6b05227

- D. Jeong, D.-S. Kwon, H.J. Kim, J. Shim, Striking a balance: exploring optimal functionalities and composition of highly adhesive and dispersing binders for high-nickel cathodes in lithium-ion batteries. Adv. Energy Mater. 13(46), 2302845 (2023). https://doi.org/10.1002/aenm.202302845

- Y. Xiao, T. Li, X. Hao, T. Zhu, J. Zang et al., Ingenious utilization of Sb-graphite composite and PVDF binder as flame-retardant and performance-improved electrode for safer lithium-ion batteries. J. Alloys Compd. 1004, 175871 (2024). https://doi.org/10.1016/j.jallcom.2024.175871

- E. Mokaripoor, I. Kazeminezhad, R. Daneshtalab, Improving the electrochemical properties of LTO/rGO nanocomposite using PVDF: PMMA as a binary composite binder in Li-ion batteries. J. Energy Storage 84, 110812 (2024). https://doi.org/10.1016/j.est.2024.110812

- K. Amine, J. Liu, I. Belharouak, High-temperature storage and cycling of C-LiFePO4/graphite Li-ion cells. Electrochem. Commun. 7(7), 669–673 (2005). https://doi.org/10.1016/j.elecom.2005.04.018

- V.H. Nguyen, W.L. Wang, E.M. Jin, H.-B. Gu, Impacts of different polymer binders on electrochemical properties of LiFePO4 cathode. Appl. Surf. Sci. 282, 444–449 (2013). https://doi.org/10.1016/j.apsusc.2013.05.149

- L. Ding, R. Leones, T. Schmeida, K. Nielsch, D. Mikhailova, Superior high-temperature rate performance of LiFePO4 cathode: The stabilizing effect of a multicomponent gel biopolymer binder. J. Power. Sources 521, 230955 (2022). https://doi.org/10.1016/j.jpowsour.2021.230955

- Y. Xu, F.Z. Chafi, P. Chen, C. Peng, Y.-J. Cheng et al., More than just a binder: versatile block copolymer enhances the electrochemical performance of a nickel-rich cathode. ACS Appl. Polym. Mater. 5(7), 4654–4663 (2023). https://doi.org/10.1021/acsapm.3c00166

- B. Jin, Z. Cui, A. Manthiram, In situ interweaved binder framework mitigating the structural and interphasial degradations of high-nickel cathodes in lithium-ion batteries. Angew. Chem. Int. Ed. 62(15), e202301241 (2023). https://doi.org/10.1002/anie.202301241

- G. Qian, L. Wang, Y. Shang, X. He, S. Tang et al., Polyimide binder: a facile way to improve safety of lithium ion batteries. Electrochim. Acta 187, 113–118 (2016). https://doi.org/10.1016/j.electacta.2015.11.019

- S.V. Ebadi, A. Fakhrali, S.O. Ranaei-Siadat, A.A. Gharehaghaji, S. Mazinani et al., Immobilization of acetylcholinesterase on electrospun poly(acrylic acid)/multi-walled carbon nanotube nanofibrous membranes. RSC Adv. 5(53), 42572–42579 (2015). https://doi.org/10.1039/C5RA03456F

- G. Zhou, K. Liu, Y. Fan, M. Yuan, B. Liu et al., An aqueous inorganic polymer binder for high performance lithium-sulfur batteries with flame-retardant properties. ACS Cent. Sci. 4(2), 260–267 (2018). https://doi.org/10.1021/acscentsci.7b00569

- R. Xu, V. Pamidi, Y. Tang, S. Fuchs, H.S. Stein et al., Greener, safer and better performing aqueous binder for positive electrode manufacturing of sodium ion batteries. Chemsuschem 17(8), e202301154 (2024). https://doi.org/10.1002/cssc.202301154

- S. Trivedi, V. Pamidi, M. Fichtner, M. Anji Reddy, Ionically conducting inorganic binders: a paradigm shift in electrochemical energy storage. Green Chem. 24(14), 5620–5631 (2022). https://doi.org/10.1039/D2GC01389D

- C. Mao, J. Dong, J. Li, X. Zhai, J. Ma et al., Toward practical all-solid-state batteries: current status of functional binders. Adv. Mater. 37(16), 2500079 (2025). https://doi.org/10.1002/adma.202500079

- R. del Olmo, T.C. Mendes, M. Forsyth, N. Casado, Mixed ionic and electronic conducting binders containing PEDOT: PSS and organic ionic plastic crystals toward carbon-free solid-state battery cathodes. J. Mater. Chem. A 10(37), 19777–19786 (2022). https://doi.org/10.1039/D1TA09628A

- Y.-J. Lee, S.-B. Hong, D.-W. Kim, Exploring the use of butadiene rubbers as a binder in composite cathodes for all-solid-state lithium batteries. J. Ind. Eng. Chem. 122, 341–348 (2023). https://doi.org/10.1016/j.jiec.2023.02.034

References

T. Liu, Y. Zhang, Z. Jiang, X. Zeng, J. Ji et al., Exploring competitive features of stationary sodium ion batteries for electrochemical energy storage. Energy Environ. Sci. 12(5), 1512–1533 (2019). https://doi.org/10.1039/C8EE03727B

M.S. Whittingham, Electrical energy storage and intercalation chemistry. Science 192(4244), 1126–1127 (1976). https://doi.org/10.1126/science.192.4244.1126

S.H. Lee, C. Johnston, P.S. Grant, Scalable, large-area printing of pore-array electrodes for ultrahigh power electrochemical energy storage. ACS Appl. Mater. Interf. 11(41), 37859–37866 (2019). https://doi.org/10.1021/acsami.9b14478

S. Ding, L. Wang, H. Dai, X. He, Prognosticating nonlinear degradation in lithium-ion batteries: operando pressure as an early indicator preceding other signals of capacity fade and safety risks. Energy Storage Mater. 75, 103998 (2025). https://doi.org/10.1016/j.ensm.2024.103998

J. Cai, X. Zhou, L. Li, Z. Yang, X. Huang et al., Kinetically dormant Ni-rich layered cathode during high-voltage operation. Adv. Mater. 37(14), e2419253 (2025). https://doi.org/10.1002/adma.202419253

L. Tong, J. Ji, Y. Zhao, L. Wang, X. He, The rise of lithium bis(fluorosulfonyl) imide: an efficient alternative to LiPF6 and functional additive in electrolytes. Mater. Today 85, 282–303 (2025). https://doi.org/10.1016/j.mattod.2025.02.018

Y. Kuk, J. Hwang, D. Nam, J. Kim, Facile synthesis of high-performance LiFePO4-reduced graphene oxide composites using ball milling. Ionics 26(6), 2803–2812 (2020). https://doi.org/10.1007/s11581-019-03395-6

J. Liu, B. Ludwig, Y. Liu, H. Pan, Y. Wang, Strengthening the electrodes for Li-ion batteries with a porous adhesive interlayer through dry-spraying manufacturing. ACS Appl. Mater. Interf. 11(28), 25081–25089 (2019). https://doi.org/10.1021/acsami.9b03020

S. Dong, L. Wang, X. Huang, J. Liang, X. He, Functionalized binders boost high-capacity anode materials. Adv. Funct. Mater. 34(41), 2404192 (2024). https://doi.org/10.1002/adfm.202404192

H. Cui, L. Wang, Y. Song, T. Lai, Z. Liu et al., Understanding electrolyte infiltration mechanisms in high-density battery electrodes: a multimodal approach. Energy Storage Mater. 75, 104094 (2025). https://doi.org/10.1016/j.ensm.2025.104094

C. Yang, D.J. Lee, H. Kim, K. Kim, J. Joo et al., Synthesis of nano-sized urchin-shaped LiFePO4 for lithium ion batteries. RSC Adv. 9(24), 13714–13721 (2019). https://doi.org/10.1039/c9ra00897g

J. Ou, L. Yang, F. Jin, S. Wu, J. Wang, High performance of LiFePO4 with nitrogen-doped carbon layers for lithium ion batteries. Adv. Powder Technol. 31(3), 1220–1228 (2020). https://doi.org/10.1016/j.apt.2019.12.044

P. Wang, G. Zhang, Z. Li, W. Sheng, Y. Zhang et al., Improved electrochemical performance of LiFePO4@N-doped carbon nanocomposites using polybenzoxazine as nitrogen and carbon sources. ACS Appl. Mater. Interf. 8(40), 26908–26915 (2016). https://doi.org/10.1021/acsami.6b10594

S.S. Zhang, K. Xu, T.R. Jow, Evaluation on a water-based binder for the graphite anode of Li-ion batteries. J. Power. Sour. 138(1–2), 226–231 (2004). https://doi.org/10.1016/j.jpowsour.2004.05.056

J.-H. Lee, S. Lee, U. Paik, Y.-M. Choi, Aqueous processing of natural graphite particulates for lithium-ion battery anodes and their electrochemical performance. J. Power. Sour. 147(1–2), 249–255 (2005). https://doi.org/10.1016/j.jpowsour.2005.01.022

Z. Zhang, T. Zeng, C. Qu, H. Lu, M. Jia et al., Cycle performance improvement of LiFePO4 cathode with polyacrylic acid as binder. Electrochim. Acta 80, 440–444 (2012). https://doi.org/10.1016/j.electacta.2012.07.054

J.S. Kim, W. Choi, K.Y. Cho, D. Byun, J. Lim et al., Effect of polyimide binder on electrochemical characteristics of surface-modified silicon anode for lithium ion batteries. J. Power. Sour. 244, 521–526 (2013). https://doi.org/10.1016/j.jpowsour.2013.02.049

Z. Zhang, T. Zeng, Y. Lai, M. Jia, J. Li, A comparative study of different binders and their effects on electrochemical properties of LiMn2O4 cathode in lithium ion batteries. J. Power. Sour. 247, 1–8 (2014). https://doi.org/10.1016/j.jpowsour.2013.08.051

S.S. Zhang, T.R. Jow, Study of poly(acrylonitrile-methyl methacrylate) as binder for graphite anode and LiMn2O4 cathode of Li-ion batteries. J. Power. Sour. 109(2), 422–426 (2002). https://doi.org/10.1016/S0378-7753(02)00107-6

I. Doberdò, N. Löffler, N. Laszczynski, D. Cericola, N. Penazzi et al., Enabling aqueous binders for lithium battery cathodes–Carbon coating of aluminum current collector. J. Power. Sour. 248, 1000–1006 (2014). https://doi.org/10.1016/j.jpowsour.2013.10.039

J. He, H. Zhong, J. Wang, L. Zhang, Investigation on xanthan gum as novel water soluble binder for LiFePO4 cathode in lithium-ion batteries. J. Alloys Compd. 714, 409–418 (2017). https://doi.org/10.1016/j.jallcom.2017.04.238

W. Zheng, S. Zhou, X. Yang, P. Wang, N. Luo et al., Mechanistic investigation of a novel aqueous binder CMC-NH4 enriched with electronegative elements on the performance of LiFePO4 cathode. J. Appl. Electrochem. (2025). https://doi.org/10.1007/s10800-025-02286-1

J. Neumann, M. Petranikova, M. Meeus, J.D. Gamarra, R. Younesi et al., Recycling of lithium-ion batteries: current state of the art, circular economy, and next generation recycling. Adv. Energy Mater. 12(17), 2102917 (2022). https://doi.org/10.1002/aenm.202102917

L. Wang, Y. Shen, Y. Liu, P. Zeng, J. Meng et al., Electrochemical restoration of battery materials guided by synchrotron radiation technology for sustainable lithium-ion batteries. Small Meth. 7(9), 2201658 (2023). https://doi.org/10.1002/smtd.202201658

J. Shim, R. Kostecki, T. Richardson, X. Song, K.A. Striebel, Electrochemical analysis for cycle performance and capacity fading of a lithium-ion battery cycled at elevated temperature. J. Power. Sour. 112(1), 222–230 (2002). https://doi.org/10.1016/S0378-7753(02)00363-4

Y. Zhang, C.-Y. Wang, X. Tang, Cycling degradation of an automotive LiFePO4 lithium-ion battery. J. Power. Sour. 196(3), 1513–1520 (2011). https://doi.org/10.1016/j.jpowsour.2010.08.070

H.-M. Kim, B.-I. Yoo, J.-W. Yi, M.-J. Choi, J.-K. Yoo, Solvent-free fabrication of thick electrodes in thermoplastic binders for high energy density lithium-ion batteries. Nanomaterials 12(19), 3320 (2022). https://doi.org/10.3390/nano12193320

Y. Kuang, C. Chen, D. Kirsch, L. Hu, Thick electrode batteries: principles, opportunities, and challenges. Adv. Energy Mater. 9(33), 1901457 (2019). https://doi.org/10.1002/aenm.201901457

X. Li, M. Wang, Q. Zhou, M. Ge, M. Zhang et al., The prilling and cocoating collaborative strategy to construct high performance of regeneration LiFePO4 materials. ACS Mater. Lett. 6(2), 640–647 (2024). https://doi.org/10.1021/acsmaterialslett.3c01161

L. Yang, Y. Tian, J. Chen, J. Gao, Z. Long et al., A high-rate capability LiFePO4/C cathode achieved by the modulation of the band structures. J. Mater. Chem. A 9(43), 24686–24694 (2021). https://doi.org/10.1039/d1ta07757k

J. Lin, Y.-H. Sun, X. Lin, Metal-organic framework-derived LiFePO4 cathode encapsulated in O, F-codoped carbon matrix towards superior lithium storage. Nano Energy 91, 106655 (2022). https://doi.org/10.1016/j.nanoen.2021.106655

A. Börger, J. Mertens, H. Wenzl, Thermal runaway and thermal runaway propagation in batteries: What do we talk about? J. Energy Storage 24, 100649 (2019). https://doi.org/10.1016/j.est.2019.01.012

X. Feng, M. Ouyang, X. Liu, L. Lu, Y. Xia et al., Thermal runaway mechanism of lithium ion battery for electric vehicles: a review. Energy Storage Mater. 10, 246–267 (2018). https://doi.org/10.1016/j.ensm.2017.05.013

X. Feng, S. Zheng, D. Ren, X. He, L. Wang et al., Investigating the thermal runaway mechanisms of lithium-ion batteries based on thermal analysis database. Appl. Energy 246, 53–64 (2019). https://doi.org/10.1016/j.apenergy.2019.04.009

H. Zhou, M. Parmananda, K.R. Crompton, M.P. Hladky, M.A. Dann et al., Effect of electrode crosstalk on heat release in lithium-ion batteries under thermal abuse scenarios. Energy Storage Mater. 44, 326–341 (2022). https://doi.org/10.1016/j.ensm.2021.10.030

J.E. Marshall, A. Zhenova, S. Roberts, T. Petchey, P. Zhu et al., On the solubility and stability of polyvinylidene fluoride. Polymers 13(9), 1354 (2021). https://doi.org/10.3390/polym13091354

M.N. Richard, J.R. Dahn, Accelerating rate calorimetry study on the thermal stability of lithium intercalated graphite in electrolyte. II. modeling the results and predicting differential scanning calorimeter curves. J. Electrochem. Soc. 146(6), 2078–2084 (1999). https://doi.org/10.1149/1.1391894

H. Maleki, G. Deng, I. Kerzhner-Haller, A. Anani, J.N. Howard, Thermal stability studies of binder materials in anodes for lithium-ion batteries. J. Electrochem. Soc. 147(12), 4470 (2000). https://doi.org/10.1149/1.1394088

A. Kriston, I. Adanouj, V. Ruiz, A. Pfrang, Quantification and simulation of thermal decomposition reactions of Li-ion battery materials by simultaneous thermal analysis coupled with gas analysis. J. Power. Sources 435, 226774 (2019). https://doi.org/10.1016/j.jpowsour.2019.226774

J. Janek, W.G. Zeier, A solid future for battery development. Nat. Energy 1(9), 16141 (2016). https://doi.org/10.1038/nenergy.2016.141

Y.-K. Sun, Promising all-solid-state batteries for future electric vehicles. ACS Energy Lett. 5(10), 3221–3223 (2020). https://doi.org/10.1021/acsenergylett.0c01977

H. Huo, J. Janek, Solid-state batteries: from ‘all-solid’ to ‘almost-solid.’ Natl. Sci. Rev. 10(6), nwas098 (2023). https://doi.org/10.1093/nsr/nwad098

Y. Zhao, Z. Liang, Y. Kang, Y. Zhou, Y. Li et al., Rational design of functional binder systems for high-energy lithium-based rechargeable batteries. Energy Storage Mater. 35, 353–377 (2021). https://doi.org/10.1016/j.ensm.2020.11.021

C. Shen, H. Yu, Z. Xue, G. Hu, Y. Cao et al., Bifunctional low molecular weight polyacrylic acid as aqueous binder and coating agent enables high performance LiMn2O4 cathode for lithium-ion batteries. Chem. Eng. J. 489, 151287 (2024). https://doi.org/10.1016/j.cej.2024.151287

W. Qi, R. Han, H. Quan, R. Guo, D. Gao et al., Self-reducing molecular ink for printed electronics and lithium-ion battery cathodes as conductive binder. J. Mater. Chem. C 12(14), 5114–5121 (2024). https://doi.org/10.1039/D3TC03636G

N. Kumano, Y. Yamaguchi, Y. Akimoto, A. Ohshima, H. Nakamura et al., Migration of binder and conductive agent during drying process of Li-ion battery cathodes. J. Power. Sources 591, 233883 (2024). https://doi.org/10.1016/j.jpowsour.2023.233883

S.-B. Hong, Y.-R. Jang, H. Kim, Y.-C. Jung, G. Shin et al., Wet-processable binder in composite cathode for high energy density all-solid-state lithium batteries. Adv. Energy Mater. 14(35), 2400802 (2024). https://doi.org/10.1002/aenm.202400802

L. Deng, J.-K. Liu, Z. Wang, J.-X. Lin, Y.-X. Liu et al., A formula to customize cathode binder for lithium ion battery. Adv. Energy Mater. 14(40), 2401514 (2024). https://doi.org/10.1002/aenm.202401514

P. Das, C.Z. Salamat, B. Zayat, R. Elizalde-Segovia, Y. Wang et al., Evaluating the impact of conjugation break spacer incorporation in poly(3, 4-propylenedioxythiophene)-based cathode binders for lithium-ion batteries. Chem. Mater. 36(3), 1413–1427 (2024). https://doi.org/10.1021/acs.chemmater.3c02555

Q. Gan, N. Qin, H. Guo, F. Zhang, H. Yuan et al., Consolidating the vulnerable interphase of Ni-rich layered cathode by multifunctional water-based binder. ACS Energy Lett. 9(4), 1562–1571 (2024). https://doi.org/10.1021/acsenergylett.4c00307

C. Li, S. Nie, H. Li, Towards efficient polymeric binders for transition metal oxides-based Li-ion battery cathodes. Chem. 30(16), e202303733 (2024). https://doi.org/10.1002/chem.202303733

M.S. Ziegler, J. Song, J.E. Trancik, Determinants of lithium-ion battery technology cost decline. Energy Environ. Sci. 14(12), 6074–6098 (2021). https://doi.org/10.1039/d1ee01313k

S. Huo, L. Sheng, W. Xue, L. Wang, H. Xu et al., Challenges of stable ion pathways in cathode electrode for all-solid-state lithium batteries: a review. Adv. Energy Mater. 13(15), 2204343 (2023). https://doi.org/10.1002/aenm.202204343

A. Mathew, W. van Ekeren, R. Andersson, M.J. Lacey, S.K. Heiskanen et al., Limitations of polyacrylic acid binders when employed in thick LNMO Li-ion battery electrodes. J. Electrochem. Soc. 171(2), 020531 (2024). https://doi.org/10.1149/1945-7111/ad242b

Q. He, J. Ning, H. Chen, Z. Jiang, J. Wang et al., Achievements, challenges, and perspectives in the design of polymer binders for advanced lithium-ion batteries. Chem. Soc. Rev. 53(13), 7091–7157 (2024). https://doi.org/10.1039/d4cs00366g

J.-O. Kim, E. Kim, E.Y. Lim, T. Kwon, I.-J. Kim et al., Stress-dissipative elastic waterborne polyurethane binders for silicon anodes with high structural integrity in lithium-ion batteries. ACS Appl. Energy Mater. 7(4), 1629–1639 (2024). https://doi.org/10.1021/acsaem.3c03099

Y. He, F. Zhou, Y. Zhang, T. Lv, P.K. Chu et al., A triple crosslinked binder with hierarchical stress dissipation and high ionic conductivity for advanced silicon anodes in lithium-ion batteries. Small 20(45), 2404556 (2024). https://doi.org/10.1002/smll.202404556

Q. Shi, S.-C. Wong, W. Ye, J. Hou, J. Zhao et al., Mechanism of adhesion between polymer fibers at nanoscale contacts. Langmuir 28(10), 4663–4671 (2012). https://doi.org/10.1021/la204633c

A. Saal, T. Hagemann, U.S. Schubert, Polymers for battery applications: active materials, membranes, and binders. Adv. Energy Mater. 11(43), 2001984 (2021). https://doi.org/10.1002/aenm.202001984

D. Shin, H. Park, U. Paik, Cross-linked poly(acrylic acid)-carboxymethyl cellulose and styrene-butadiene rubber as an efficient binder system and its physicochemical effects on a high energy density graphite anode for Li-ion batteries. Electrochem. Commun. 77, 103–106 (2017). https://doi.org/10.1016/j.elecom.2017.02.018

S. Huang, X. Huang, Y. Huang, X. He, H. Zhuo et al., Rational design of effective binders for LiFePO4 cathodes. Polymers 13(18), 3146 (2021). https://doi.org/10.3390/polym13183146

S. Hu, Y. Li, J. Yin, H. Wang, X. Yuan et al., Effect of different binders on electrochemical properties of LiFePO4/C cathode material in lithium ion batteries. Chem. Eng. J. 237, 497–502 (2014). https://doi.org/10.1016/j.cej.2013.08.119

J.L. Olmedo-Martínez, L. Meabe, A. Basterretxea, D. Mecerreyes, A.J. Müller, Effect of chemical structure and salt concentration on the crystallization and ionic conductivity of aliphatic polyethers. Polymers 11(3), 452 (2019). https://doi.org/10.3390/polym11030452

Y. Komoda, K. Ishibashi, K. Kuratani, K. Suzuki, N. Ohmura et al., Effects of drying rate and slurry microstructure on the formation process of LiB cathode and electrochemical properties. J. Power. Sour. 568, 232983 (2023). https://doi.org/10.1016/j.jpowsour.2023.232983

A.D. Pasquier, F. Disma, T. Bowmer, A.S. Gozdz, G. Amatucci et al., Differential scanning calorimetry study of the reactivity of carbon anodes in plastic Li-ion batteries. J. Electrochem. Soc. 145(2), 472–477 (1998). https://doi.org/10.1149/1.1838287

J. Liang, D. Chen, K. Adair, Q. Sun, N.G. Holmes et al., Insight into prolonged cycling life of 4 V all-solid-state polymer batteries by a high-voltage stable binder. Adv. Energy Mater. 11(1), 2002455 (2021). https://doi.org/10.1002/aenm.202002455

R. Wang, L. Feng, W. Yang, Y. Zhang, Y. Zhang et al., Effect of different binders on the electrochemical performance of metal oxide anode for lithium-ion batteries. Nanoscale Res. Lett. 12(1), 575 (2017). https://doi.org/10.1186/s11671-017-2348-6

A. Fedorková, R. Oriňáková, A. Oriňák, I. Talian, A. Heile et al., PPy doped PEG conducting polymer films synthesized on LiFePO4 ps. J. Power. Sour. 195(12), 3907–3912 (2010). https://doi.org/10.1016/j.jpowsour.2010.01.003

S. Roberts, L. Chen, B. Kishore, C.E.J. Dancer, M.J.H. Simmons et al., Mechanism of gelation in high nickel content cathode slurries for sodium-ion batteries. J. Colloid Interf. Sci. 627, 427–437 (2022). https://doi.org/10.1016/j.jcis.2022.07.033

C.-H. Tsao, C.-H. Hsu, P.-L. Kuo, Ionic Conducting and Surface Active Binder of Poly (ethylene oxide)-block-poly(acrylonitrile) for High Power Lithium-ion Battery. Electrochim. Acta 196, 41–47 (2016). https://doi.org/10.1016/j.electacta.2016.02.154

I. Aldalur, H. Zhang, M. Piszcz, U. Oteo, L.M. Rodriguez-Martinez et al., Jeffamine® based polymers as highly conductive polymer electrolytes and cathode binder materials for battery application. J. Power. Sour. 347, 37–46 (2017). https://doi.org/10.1016/j.jpowsour.2017.02.047

A.C. Luntz, B.D. McCloskey, Nonaqueous Li-air batteries: a status report. Chem. Rev. 114(23), 11721–11750 (2014). https://doi.org/10.1021/cr500054y

B. Chang, D.H. Yun, I. Hwang, J.K. Seo, J. Kang et al., Carrageenan as a sacrificial binder for 5 V LiNi0.5 Mn1.5 O4 cathodes in lithium-ion batteries. Adv. Mater. 35(45), e2303787 (2023). https://doi.org/10.1002/adma.202303787

A. Guerfi, M. Kaneko, M. Petitclerc, M. Mori, K. Zaghib, LiFePO4 water-soluble binder electrode for Li-ion batteries. J. Power. Sour. 163(2), 1047–1052 (2007). https://doi.org/10.1016/j.jpowsour.2006.09.067

H. Tang, Q. Weng, Z. Tang, Chitosan oligosaccharides: a novel and efficient water soluble binder for lithium zinc titanate anode in lithium-ion batteries. Electrochim. Acta 151, 27–34 (2015). https://doi.org/10.1016/j.electacta.2014.11.002

X. Liu, M. Zhang, X. Peng, M. Li et al., Se–Se bonds involved polyurethane-based binders for enhanced redox kinetics in lithium-ion batteries. ACS Appl. Polym. Mater. 7(6), 4019–4028 (2025). https://doi.org/10.1021/acsapm.5c00401

C. Liang, Z. Li, Y. Chen, Y. Zhang, Y. Liu et al., Design and preparation of soluble polyimide binder with random copolymerized rigid-flexible segments for lithium ion batteries. J. Appl. Polym. Sci. 142(14), e56709 (2025). https://doi.org/10.1002/app.56709

Y. Hu, C. Wang, G. Zhu, J. Xu, L. Wang et al., POLY(amidoamine) dendrimer-induced 3D crosslinked network binder for LiFePO4 cathode: endowing battery with superior cycling stability. J. Electrochem. Soc. 170(3), 030547 (2023). https://doi.org/10.1149/1945-7111/acc6f4

F. Zhang, H. Xia, T. Wei, B. Liu, H. Li et al., Rotatable methylene ether bridge units enabling high chain flexibility and rapid ionic transport in a new universal aqueous conductive binder. Adv. Funct. Mater. 33(34), 2303339 (2023). https://doi.org/10.1002/adfm.202303339

Y. Xu, Y. Wang, N. Dong, C. Pu, B. Liu et al., Novel polyimide binder for achieving high-rate capability and long-term cycling stability of LiNi0.8Co0.1Mn0.1O2 cathode via constructing polar and micro-branched crosslinking network structure. J. Energy Chem. 76, 19–31 (2023). https://doi.org/10.1016/j.jechem.2022.09.008

C. Ye, L. Wang, Q. Tan, Y. Ma, Q. Tong et al., Conducting polyacrylamide–polyaniline polymers as water-soluble binder in LiFePO4 cathode for lithium-ion batteries. Energy Technol. 11(9), 2300464 (2023). https://doi.org/10.1002/ente.202300464

J. He, J. Wang, H. Zhong, J. Ding, L. Zhang, Cyanoethylated carboxymethyl chitosan as water soluble binder with enhanced adhesion capability and electrochemical performances for LiFePO4 cathode. Electrochim. Acta 182, 900–907 (2015). https://doi.org/10.1016/j.electacta.2015.10.006

J. Huang, J. Wang, H. Zhong, L. Zhang, N-cyanoethyl polyethylenimine as a water-soluble binder for LiFePO4 cathode in lithium-ion batteries. J. Mater. Sci. 53(13), 9690–9700 (2018). https://doi.org/10.1007/s10853-018-2247-y

J.-C. Daigle, F. Barray, C. Gagnon, D. Clément, P. Hovington et al., Amphiphilic latex as a water-based binder for LiFePO4 cathode. J. Power. Sour. 415, 172–178 (2019). https://doi.org/10.1016/j.jpowsour.2019.01.054

H. Peng, L. Liu, Q. Zhang, S. Liu, M. Lin et al., A fluorine-free polysulfone-polyamide-polyimide copolymer binder for LiNi0.8Co0.1Mn0.1O2 cathode in lithium-ion battery. Chin. J. Polym. Sci. (2025). https://doi.org/10.1007/s10118-025-3281-2

Y. Wang, N. Dong, B. Liu, G. Tian, S. Qi et al., Self-adaptive gel poly(imide-siloxane) binder ensuring stable cathode-electrolyte interface for achieving high-performance NCM811 cathode in lithium-ion batteries. Energy Storage Mater. 56, 621–630 (2023). https://doi.org/10.1016/j.ensm.2023.02.002

J. He, H. Zhong, L. Zhang, Water-soluble binder PAALi with terpene resin emulsion as tackifier for LiFePO4 cathode. J. Appl. Polym. Sci. 135(14), 46132 (2018). https://doi.org/10.1002/app.46132

A. Oishi, R. Tatara, E. Togo, H. Inoue, S. Yasuno et al., Sulfated alginate as an effective polymer binder for high-voltage LiNi0.5Mn1.5O4 electrodes in lithium-ion batteries. ACS Appl. Mater. Interfaces 14(46), 51808–51818 (2022). https://doi.org/10.1021/acsami.2c11695

D. Shao, J. Huang, A. Wu, Y. Fang, X. Li et al., Synthesis of N-ethyl carboxylic acid functionalized polyethylenimine as self-crosslinking aqueous binder for LiFePO4 cathode of lithium-ion batteries. Energy Technol. 13(5), 2402066 (2025). https://doi.org/10.1002/ente.202402066

A. Weber, N. Keim, P. Koch, M. Müller, W. Bauer et al., The impact of binder polarity on the properties of aqueously processed positive and negative electrodes for lithium-ion batteries. Sci. Rep. 15(1), 10024 (2025). https://doi.org/10.1038/s41598-025-93813-9

P.P. Prosini, M. Carewska, C. Cento, A. Masci, Poly vinyl acetate used as a binder for the fabrication of a LiFePO4-based composite cathode for lithium-ion batteries. Electrochim. Acta 150, 129–135 (2014). https://doi.org/10.1016/j.electacta.2014.10.123

M. Sun, H. Zhong, S. Jiao, H. Shao, L. Zhang, Investigation on carboxymethyl chitosan as new water soluble binder for LiFePO4 cathode in Li-ion batteries. Electrochim. Acta 127, 239–244 (2014). https://doi.org/10.1016/j.electacta.2014.02.027

W. Porcher, B. Lestriez, S. Jouanneau, D. Guyomard, Design of aqueous processed thick LiFePO4 composite electrodes for high-energy lithium battery. J. Electrochem. Soc. 156(3), A133 (2009). https://doi.org/10.1149/1.3046129

G.T. Kim, S.S. Jeong, M. Joost, E. Rocca, M. Winter et al., Use of natural binders and ionic liquid electrolytes for greener and safer lithium-ion batteries. J. Power. Sour. 196(4), 2187–2194 (2011). https://doi.org/10.1016/j.jpowsour.2010.09.080

Z.P. Cai, Y. Liang, W.S. Li, L.D. Xing, Y.H. Liao, Preparation and performances of LiFePO4 cathode in aqueous solvent with polyacrylic acid as a binder. J. Power. Sour. 189(1), 547–551 (2009). https://doi.org/10.1016/j.jpowsour.2008.10.040

Z. Zhang, T. Zeng, H. Lu, M. Jia, J. Li et al., Enhanced high-temperature performances of LiFePO4 cathode with polyacrylic acid as binder. ECS Electrochem. Lett. 1(5), A74–A76 (2012). https://doi.org/10.1149/2.001206eel

J. Sun, X. Ren, Z. Li, W. Tian, Y. Zheng et al., Effect of poly (acrylic acid)/Poly (vinyl alcohol) blending binder on electrochemical performance for lithium iron phosphate cathodes. J. Alloys Compd. 783, 379–386 (2019). https://doi.org/10.1016/j.jallcom.2018.12.197

C.-C. Li, Y.-S. Lin, Interactions between organic additives and active powders in water-based lithium iron phosphate electrode slurries. J. Power. Sour. 220, 413–421 (2012). https://doi.org/10.1016/j.jpowsour.2012.07.125

Y. Wang, M. Ji, T. Zhu, L. Wang, Y. Zhou et al., Multifunctional amino-functionalized Zr-based metal-organic frameworks: a breakthrough in enhancing the stability and performance of Ni-rich cathode Li metal batteries in water-prone environments. Energy Storage Mater. 77, 104217 (2025). https://doi.org/10.1016/j.ensm.2025.104217

A.C. Rolandi, C. Pozo-Gonzalo, I. de Meatza, N. Casado, D. Mecerreyes et al., Fluorine-free poly(ionic liquid)s binders for the aqueous processing of high-voltage NMC811 cathodes. Adv. Energy Sustain. Res. 4(12), 2300149 (2023). https://doi.org/10.1002/aesr.202300149

L. Rao, X. Jiao, C.-Y. Yu, A. Schmidt, C. O’Meara et al., Multifunctional composite binder for thick high-voltage cathodes in lithium-ion batteries. ACS Appl. Mater. Interf. 14(1), 861–872 (2022). https://doi.org/10.1021/acsami.1c19554

J. Shin, J.-H. Lee, J.K. Seo, W.T.A. Ran, S.M. Hwang et al., Carbon nanotubes-coated Ni-rich cathodes for the green manufacturing process of lithium-ion batteries. Int. J. Energy Res. 46(11), 16061–16074 (2022). https://doi.org/10.1002/er.8266

M. Ryu, Y.K. Hong, S.Y. Lee, J.H. Park, Ultrahigh loading dry-process for solvent-free lithium-ion battery electrode fabrication. Nat. Commun. 14(1), 1316 (2023). https://doi.org/10.1038/s41467-023-37009-7

H. Kim, J.H. Lim, T. Lee, J. An, H. Kim et al., Ozone-treated carbon nanotube as a conductive agent for dry-processed lithium-ion battery cathode. ACS Energy Lett. 8(8), 3460–3466 (2023). https://doi.org/10.1021/acsenergylett.3c00936

E. Wiegmann, S. Fischer, M. Leeb, A. Kwade, Sustainable lithium Ferro-phosphate cathode manufacturing: a semi-dry approach with water-based processing and polytetrafluorethylene binders. Batteries 9(12), 567 (2023). https://doi.org/10.3390/batteries9120567

Z. Zhang, D. Han, M. Xiao, S. Wang, Y. Feng et al., New potential substitute of PVDF binder: poly(propylene carbonate) for solvent-free manufacturing high-loading cathodes of LiFePO4|Li batteries. Ionics 29(10), 3895–3906 (2023). https://doi.org/10.1007/s11581-023-05108-6

B. Emley, C. Wu, L. Zhao, Q. Ai, Y. Liang et al., Impact of fabrication methods on binder distribution and charge transport in composite cathodes of all-solid-state batteries. Mater. Futur. 2(4), 045102 (2023). https://doi.org/10.1088/2752-5724/acefe6

S.-B. Hong, Y.-J. Lee, U.-H. Kim, C. Bak, Y.M. Lee et al., All-solid-state lithium batteries: Li+-conducting ionomer binder for dry-processed composite cathodes. ACS Energy Lett. 7(3), 1092–1100 (2022). https://doi.org/10.1021/acsenergylett.1c02756

T.J. Embleton, J.H. Choi, S.-J. Won, J. Ali, K.S. Saqib et al., High-energy density ultra-thick drying-free Ni-rich cathode electrodes for application in Lithium-ion batteries. Energy Storage Mater. 71, 103542 (2024). https://doi.org/10.1016/j.ensm.2024.103542

A.C. Kıgılcım, M.E. Cetintasoglu, İ. University, M. Tokur et al., Versatile spiro-fluorene-based polymer binder for Li-ion batteries. ACS Appl. Polym. Mater. 7(4), 2708–2715 (2025). https://doi.org/10.1021/acsapm.5c00081

R. Jeong, J. Lee, Y.-T. Kim, J. Choi, Lithiated cellulose nanofibers as a water-soluble binder for high-rate nanosized LiFePO4/C cathodes: Comparative degradation mechanisms across binder systems. Chem. Eng. J. 510, 161668 (2025). https://doi.org/10.1016/j.cej.2025.161668

Y. Yu, C. Yang, Y. Jiang, J. Zhu, J. Zhang et al., Consecutive covalent bonds reconstruct robust dual-interfaces by carbonized binder to enable conductive-additive-free durable silicon anode. Nano Energy 130, 110108 (2024). https://doi.org/10.1016/j.nanoen.2024.110108

X. Lu, G.J. Lian, J. Parker, R. Ge, M.K. Sadan et al., Effect of carbon blacks on electrical conduction and conductive binder domain of next-generation lithium-ion batteries. J. Power. Sour. 592, 233916 (2024). https://doi.org/10.1016/j.jpowsour.2023.233916

W. Geng, X. Hu, Q. Zhou, Y. Zhang, B. He et al., Rational design of trifunctional conductive binder for high-performance Si anodes in lithium-ion batteries. J. Power. Sour. 601, 234285 (2024). https://doi.org/10.1016/j.jpowsour.2024.234285

R. Del Olmo, G. Guzmán-González, O. Sanz, M. Forsyth, N. Casado, Versatile mixed ionic-electronic conducting binders for high-power, high-energy batteries. Electrochim. Acta 474, 143547 (2024). https://doi.org/10.1016/j.electacta.2023.143547

Q. Zhang, Z. Sha, X. Cui, S. Qiu, C. He et al., Incorporation of redox-active polyimide binder into LiFePO4 cathode for high-rate electrochemical energy storage. Nanotechnol. Rev. 9(1), 1350–1358 (2020). https://doi.org/10.1515/ntrev-2020-0092

T. Tamura, Y. Aoki, T. Ohsawa, K. Dokko, Polyaniline as a functional binder for LiFePO4 cathodes in lithium batteries. Chem. Lett. 40(8), 828–830 (2011). https://doi.org/10.1246/cl.2011.828

S. Huang, H. Chen, M. Chen, Y. Huang, X. He et al., Design of conductive binders for LiFePO4 cathodes with long-term cycle life. ACS Sustain. Chem. Eng. 9(39), 13277–13286 (2021). https://doi.org/10.1021/acssuschemeng.1c04552

T. Liu, R. Parekh, P. Mocny, B.P. Bloom, Y. Zhao et al., Tailored PVDF graft copolymers via ATRP as high-performance NCM811 cathode binders. ACS Mater. Lett. 5(10), 2594–2603 (2023). https://doi.org/10.1021/acsmaterialslett.3c00485

L. Qiu, Z. Shao, D. Wang, W. Wang, F. Wang et al., Enhanced electrochemical properties of LiFePO4 (LFP) cathode using the carboxymethyl cellulose lithium (CMC-Li) as novel binder in lithium-ion battery. Carbohydr. Polym. 111, 588–591 (2014). https://doi.org/10.1016/j.carbpol.2014.05.027

L. Qiu, Z. Shao, W. Wang, F. Wang, J. Wang et al., Enhanced Cyclability of C/Lithium Iron Phosphate Cathodes with a Novel water-soluble lithium-ion binder. Electrochim. Acta 145, 11–18 (2014). https://doi.org/10.1016/j.electacta.2014.08.042

X. Su, H. Fang, H. Yang, F. Zou, G. Li et al., Cellulose sulfate lithium as a conductive binder for LiFePO4 cathode with long cycle life. Carbohydr. Polym. 313, 120848 (2023). https://doi.org/10.1016/j.carbpol.2023.120848

S. Huang, J. Ren, R. Liu, Y. Bai, X. Li et al., Enhanced electrochemical properties of LiFePO4 cathode using waterborne lithiated ionomer binder in Li-ion batteries with low amount. ACS Sustain. Chem. Eng. 6(10), 12650–12657 (2018). https://doi.org/10.1021/acssuschemeng.8b01532

M. Ghahramani, S. Hamidi, M. Mohammad, M. Javanbakht, P. Gorji, The effect of sulfonated copolymer as a binder on the electrochemical performance of LiFePO4 cathode for lithium-ion batteries. J. Electroanal. Chem. 936, 117342 (2023). https://doi.org/10.1016/j.jelechem.2023.117342

V.A. Nguyen, C. Kuss, Review: conducting polymer-based binders for lithium-ion batteries and beyond. J. Electrochem. Soc. 167(6), 065501 (2020). https://doi.org/10.1149/1945-7111/ab856b

T. Liu, C.-J. Tong, B. Wang, L.-M. Liu, S. Zhang et al., Trifunctional electrode additive for high active material content and volumetric lithium-ion electrode densities. Adv. Energy Mater. 9(10), 1803390 (2019). https://doi.org/10.1002/aenm.201803390

S.N. Eliseeva, O.V. Levin, E.G. Tolstopjatova, E.V. Alekseeva, R.V. Apraksin et al., New functional conducting poly-3, 4-ethylenedioxythiopene: polystyrene sulfonate/carboxymethylcellulose binder for improvement of capacity of LiFePO4-based cathode materials. Mater. Lett. 161, 117–119 (2015). https://doi.org/10.1016/j.matlet.2015.08.078

H. Zhong, A. He, J. Lu, M. Sun, J. He et al., Carboxymethyl chitosan/conducting polymer as water-soluble composite binder for LiFePO4 cathode in lithium ion batteries. J. Power. Sour. 336, 107–114 (2016). https://doi.org/10.1016/j.jpowsour.2016.10.041

A.V. Kubarkov, O.A. Drozhzhin, E.A. Karpushkin, K.J. Stevenson, E.V. Antipov et al., Poly(3, 4-ethylenedioxythiophene): poly(styrenesulfonic acid)–polymer composites as functional cathode binders for high power LiFePO4 batteries. Colloid Polym. Sci. 297(3), 475–484 (2019). https://doi.org/10.1007/s00396-018-04468-0

W. Dou, G. Wan, T. Liu, L. Han, W. Zhang et al., Conductive composite binder for recyclable LiFePO4 cathode. Chin. Chem. Lett. 35(11), 109389 (2024). https://doi.org/10.1016/j.cclet.2023.109389

S. Dong, K. Zhu, X. Dong, G. Dong, Y. Gao et al., A novel graphene based bi-function humidity tolerant binder for lithium-ion battery. Small Meth. 7(7), 2201393 (2023). https://doi.org/10.1002/smtd.202201393

G.T. Pace, M.L. Le, R.J. Clément, R.A. Segalman, A coacervate-based mixed-conducting binder for high-power, high-energy batteries. ACS Energy Lett. 8(6), 2781–2788 (2023). https://doi.org/10.1021/acsenergylett.3c00829

Y.-K. Hong, J.-H. Kim, N.-Y. Kim, K.-S. Oh, H.-I. Kim et al., Cellulose elementary fibrils as deagglomerated binder for high-mass-loading lithium battery electrodes. Nano-Micro Lett. 17(1), 112 (2025). https://doi.org/10.1007/s40820-024-01642-8

Y. Shi, X. Zhou, J. Zhang, A.M. Bruck, A.C. Bond et al., Nanostructured conductive polymer gels as a general framework material to improve electrochemical performance of cathode materials in Li-ion batteries. Nano Lett. 17(3), 1906–1914 (2017). https://doi.org/10.1021/acs.nanolett.6b05227

D. Jeong, D.-S. Kwon, H.J. Kim, J. Shim, Striking a balance: exploring optimal functionalities and composition of highly adhesive and dispersing binders for high-nickel cathodes in lithium-ion batteries. Adv. Energy Mater. 13(46), 2302845 (2023). https://doi.org/10.1002/aenm.202302845

Y. Xiao, T. Li, X. Hao, T. Zhu, J. Zang et al., Ingenious utilization of Sb-graphite composite and PVDF binder as flame-retardant and performance-improved electrode for safer lithium-ion batteries. J. Alloys Compd. 1004, 175871 (2024). https://doi.org/10.1016/j.jallcom.2024.175871

E. Mokaripoor, I. Kazeminezhad, R. Daneshtalab, Improving the electrochemical properties of LTO/rGO nanocomposite using PVDF: PMMA as a binary composite binder in Li-ion batteries. J. Energy Storage 84, 110812 (2024). https://doi.org/10.1016/j.est.2024.110812

K. Amine, J. Liu, I. Belharouak, High-temperature storage and cycling of C-LiFePO4/graphite Li-ion cells. Electrochem. Commun. 7(7), 669–673 (2005). https://doi.org/10.1016/j.elecom.2005.04.018

V.H. Nguyen, W.L. Wang, E.M. Jin, H.-B. Gu, Impacts of different polymer binders on electrochemical properties of LiFePO4 cathode. Appl. Surf. Sci. 282, 444–449 (2013). https://doi.org/10.1016/j.apsusc.2013.05.149

L. Ding, R. Leones, T. Schmeida, K. Nielsch, D. Mikhailova, Superior high-temperature rate performance of LiFePO4 cathode: The stabilizing effect of a multicomponent gel biopolymer binder. J. Power. Sources 521, 230955 (2022). https://doi.org/10.1016/j.jpowsour.2021.230955

Y. Xu, F.Z. Chafi, P. Chen, C. Peng, Y.-J. Cheng et al., More than just a binder: versatile block copolymer enhances the electrochemical performance of a nickel-rich cathode. ACS Appl. Polym. Mater. 5(7), 4654–4663 (2023). https://doi.org/10.1021/acsapm.3c00166

B. Jin, Z. Cui, A. Manthiram, In situ interweaved binder framework mitigating the structural and interphasial degradations of high-nickel cathodes in lithium-ion batteries. Angew. Chem. Int. Ed. 62(15), e202301241 (2023). https://doi.org/10.1002/anie.202301241

G. Qian, L. Wang, Y. Shang, X. He, S. Tang et al., Polyimide binder: a facile way to improve safety of lithium ion batteries. Electrochim. Acta 187, 113–118 (2016). https://doi.org/10.1016/j.electacta.2015.11.019

S.V. Ebadi, A. Fakhrali, S.O. Ranaei-Siadat, A.A. Gharehaghaji, S. Mazinani et al., Immobilization of acetylcholinesterase on electrospun poly(acrylic acid)/multi-walled carbon nanotube nanofibrous membranes. RSC Adv. 5(53), 42572–42579 (2015). https://doi.org/10.1039/C5RA03456F

G. Zhou, K. Liu, Y. Fan, M. Yuan, B. Liu et al., An aqueous inorganic polymer binder for high performance lithium-sulfur batteries with flame-retardant properties. ACS Cent. Sci. 4(2), 260–267 (2018). https://doi.org/10.1021/acscentsci.7b00569

R. Xu, V. Pamidi, Y. Tang, S. Fuchs, H.S. Stein et al., Greener, safer and better performing aqueous binder for positive electrode manufacturing of sodium ion batteries. Chemsuschem 17(8), e202301154 (2024). https://doi.org/10.1002/cssc.202301154

S. Trivedi, V. Pamidi, M. Fichtner, M. Anji Reddy, Ionically conducting inorganic binders: a paradigm shift in electrochemical energy storage. Green Chem. 24(14), 5620–5631 (2022). https://doi.org/10.1039/D2GC01389D

C. Mao, J. Dong, J. Li, X. Zhai, J. Ma et al., Toward practical all-solid-state batteries: current status of functional binders. Adv. Mater. 37(16), 2500079 (2025). https://doi.org/10.1002/adma.202500079

R. del Olmo, T.C. Mendes, M. Forsyth, N. Casado, Mixed ionic and electronic conducting binders containing PEDOT: PSS and organic ionic plastic crystals toward carbon-free solid-state battery cathodes. J. Mater. Chem. A 10(37), 19777–19786 (2022). https://doi.org/10.1039/D1TA09628A

Y.-J. Lee, S.-B. Hong, D.-W. Kim, Exploring the use of butadiene rubbers as a binder in composite cathodes for all-solid-state lithium batteries. J. Ind. Eng. Chem. 122, 341–348 (2023). https://doi.org/10.1016/j.jiec.2023.02.034